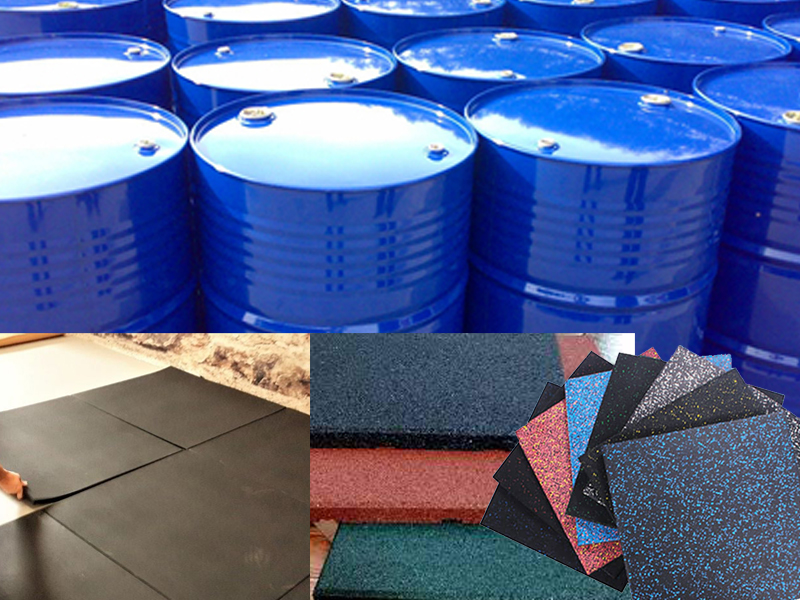

Cork Binder

Polyurethane Composition: The binder is primarily composed of polyurethane, a versatile polymer known for its excellent bonding properties, durability, and flexibility. Polyurethane binders are commonly used in cork-based products due to their ability to form strong and resilient bonds.

MDI-Based Formulation: The binder is based on MDI (Methylene Diphenyl Diisocyanate), which is a type of isocyanate commonly used in polyurethane formulations. MDI offers excellent reactivity and contributes to the overall strength and resilience of the cork composite material.

Solvent-Free and Moisture-Cure: One of the notable features of this binder is that it is solvent-free and moisture-cure. This means that it cures and forms bonds in the presence of moisture, eliminating the need for additional solvents and providing a safer and more environmentally friendly adhesive solution.

Compatibility with Recycled Wooden Particles and Mulch: The binder is specifically formulated for binding recycled wooden particles and mulch together to create cork-based materials. These recycled materials are commonly sourced from post-consumer waste or industrial by-products, making the binder suitable for eco-friendly manufacturing processes.

Versatility: The binder is suitable for various cork-based products, including cork stoppers, cork boards, cork handicrafts, and other cork composite materials. Its versatility allows for the production of products with different densities, hardness levels, and surface finishes.

Excellent Bonding Properties: The binder forms strong and durable bonds between the recycled wooden particles and mulch, ensuring that the resulting cork composite material exhibits uniform density and resilience. This enhances the performance and longevity of cork-based products in various applications.

Customization Options: Manufacturers may have the flexibility to customize the formulation of the binder to meet specific requirements, such as adjusting the curing time, viscosity, or other properties to optimize production processes and product performance.

Ease of Handling: The binder may be formulated for easy handling and application in manufacturing processes, whether through spray application, mixing with wooden particles and mulch, or other methods. This facilitates efficient production and consistent product quality.

Environmental Considerations: In addition to being solvent-free, the binder may be formulated to minimize environmental impact, such as by using recycled materials or incorporating sustainable practices into the manufacturing process. This aligns with growing consumer demand for eco-friendly products.